- Your cart is empty Browse Shop

Showing 13–21 of 21 results

-

SHSB – 300 – HEAVY DUTY SINGLE PHASER

SHSB – 300 – HEAVY DUTY SINGLE PHASER

FLUTE ROLL:

- 1 SET OF FLUTE ROLL BEARING.

- THE CENTER FLUTE ROLLER 320 MM DIA HUNDERED

- UPTO 50 HRC, GRINDED / HARD CROME PLATED.

- TOP ROLL 300 MM DIA HARDENED UPTO 50 HRC,

- GRINDED / HARD CROME PLATED.

- PRESSURE ROLL DIA 320 MM.

-

SHSB – 320 HEAVY DUTY SINGLE PHASER

SHSB – 320 HEAVY DUTY SINGLE PHASER

FLUTE ROLL:

▪ 1 SET OF FLUTE ROLL BEARING.

▪ THE CENTRE FLUTE ROLLER 320 MM DIA HUNDRED UPTO 50 HRC, GRINDED / HARD CROME PLATED.

▪ TOP ROLL 300 MM DIA HARDENED UPTO 50 HRC, GRINDED / HARD CROME PLATED.

▪ PRESSURE ROLL DIA 320 MM.

▪ COMPLETE FRAME OF THIS HEAVY DUTY SINGLE FACE CORRUGATING MACHINE IS FABRICATED FROM MILD STEEL TO ABSORB VIBRATION AND ACHIEVE SPEED.

▪ FLUTE ROLLERS ARE FIXED ON THIS MACHINE OR WITH LATEST DOUBLE BEARING SYSTEM, TO ABSORB HIGH SPEED VIBRATION AND DELIVER MAXIMUM SPEED.

▪ VACUUM SUCTION IS PROVIDED AND INSTEAD OF ADOPTER FOR FINGERLESS SYSTEM.

▪ THE ROLLER ARE GRINDED AND HARD CHROME PLATING UP TO 40 MICRONS IS COATED ON THE FLUTE ROLLERS.

▪ INDIVIDUAL DRIVE BOX {GEAR BOX} SEPARATING DYNAMIC OSCILLATING, IMPROVES RUNNING STABILITY.

▪ TRANSMISSION SHAFT’S ABSORBS ALL VIBRATION GENERATED BY THE GEAR BOX, THEREFORE SMOOTH TRANSMISSION IS PASSED ON TO THE CORRUGATING FLUTE ROLLERS AND GUM APPLICANT ROLLER

· FLUTE ROLLER AND PRESSURE ROLLER ARE PNEUMATICALLY CONTROLLED WITH PRESSURE ADJUSTING SYSTEM PROVIDED IN THE CONTROL PANEL.

· GLUE APPLICATOR ROLL ENGAGING OR DISENGAGING AS WELL FLUTE FORMATION ARE ALL PNEUMATICALLY CONTROLLED

· SELF CIRCULATING GLUE SUPPLYING SYSTEM IS AVAILABLE

· MANUAL ADJUSTMENT SCREW HANDLE SYSTEM IS PROVIDED TO ADJUST GLUE APPLICATION AS PER THE PAPER ROLLER SIZE.

· DESIGNED SPEED 120 MTR PER MIN

· AIR COMPRESSOR NOT IN OUR SCOPE. -

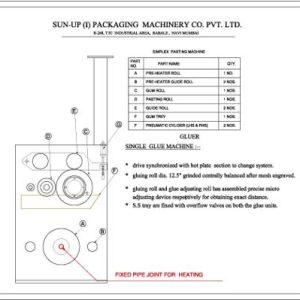

SIMPLEX PASTING MACHINE

SIMPLEX PASTING MACHINE

• LATEST INDIVIDUAL DRIVE SYSTEM FOR EACH LAYER SIMPLIFIES MECHANICAL STRUCTURED.

• UNUSED LAYERS CAN BE TURNED OF AND SO AS TO AVOID ENERGY WASTE.

• ADJUSTMENT FOR GAPS BETWEEN APPLICATOR ROLL AND PRESSURE ROLL AND FINE TUNING ON INDIVIDUAL SAME SIDE GLUE SETTING AVAILABLE ON THE MACHINE.

• FREQUENCY CONVEYOR CONTROLLED AUTOMATICALLY VARIES WITH SPEED OF PRODUCTION LINE. ALSO KNOWN AS AUTOMATIC PORTING SYSTEM.

• DRIVE FROM MOTORS ARE THROUGH TIMING BELTS TO AVOID ANY VARIATION ON GLUE APPLICATION ON LINER.

• PRE-HEATER FOR BOTTOM PAPER FIXED ON THE MACHINE FOR BETTER PERFORMANCE OF THE BOARD.

• A PERFECT DIGREE/ANGLE IS DESIGNED ON THIS MACHINE TO APPLY MINIMUM GLUE ON THE LINER.

• ARRANGMENT ARE PROVIDED IN THIS MACHINE TO CONTROLLED ANY FLUTE CRUSH WHILE GETTING GLUED. -

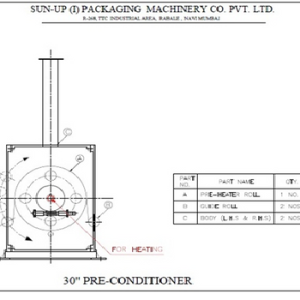

SIMPLEX PRE HEATER

SIMPLEX PRE HEATER

L.H.S & R.H.S FRAME OF THIS IS FABRICATED FROM MILD STEEL.

WRAP AROUND PRE-HEATER 30″ DIAMETER SHALL BE FIXED BEFORE CORRUGATION MACHINE FOR THE BOTTOM PAPER AND BEHIND FOR

FLUTING PAPER.GEAR MOTOR ALONG WITH WORM GEAR SYSTEM IS PROVIDED, WRAP AROUND SHALL HELP IN ACHIEVING THE EXACT AMOUNT OF HEAT

REQUIRED ON PAPER TO MAINTAIN MOISTER ON PAPERSPECIALLY DESIGNED FOR STEAM HEATING SYSTEM. PRESSURE NEEDED 1.1 -1.2 MPA.

-

SLITTER SCORER

SLITTER SCORER:

MACHINE DESCRIPTION:

▪ THIS MACHINE IS EQUIPPED FOR THE PRODUCT LINE THAT THE SPEED ABOVE 100M/MIN, 3-5

▪ SECOND EXCHANGE ORDER, CHANGE ORDER FAST, AND DESIGNED FOR SLITTING AND CUTTING BOARD FOR THE CARTON PRODUCT LINE. WHEN YOU OPERATE, DON’T OVERSTEP THE DESIGNING BOUND. IF YOU HAVE PROBLEM YOU SHOULD CONSULT US.

▪ THE ELECTRO MAGNETISM VALVE OF PNEUMATIC CYLINDER CONTROL HIGH SPEED LINES.

▪ PNEUMATIC CYLINDER: DIA 63*ST150-5 / FIVE (BY KNIFES)

▪ PNEUMATIC CYLINDER: DIA 63*ST100-16 / SIXTEEN (BY LINE)

▪ THE IMPORTED BALL BARING SCREW CONTROL THE BLADE AND THE ANVIL, THE LEFT AND RIGHT SCORERS. IT CAN BE MANUALY.CONTROL

▪ THIN BLADE (1.2MM) SLITTER SYSTEM. WITH ANVIL FOR CUTTING,

▪ THE IN VISION IS TRIM AND THE WASTE WILL BE 5MM AT LEAST. AND EACH BLADE WITH AUTOMATIC SHARPENING EQUIPMENT, ENSURE THE CUTTING PRECISION AND LIFE OF THE BLADE.

▪ WITH HIGH QUALITY TUNGSTEN STEEL BLADE, THE BLADE CAN CUT PAPER WITHIN 5-8 MILLION METERS, ORDINARY BLADE WITHOUT TUNGSTEN COATING SHALL RUN FOR 2 MILLION METERS -

STACKER FOR N C CUT OFF MACHINE

STACKER FOR N C CUT OFF MACHINE

· STACKER SHALL BE INSTALLED AFTER N.C CUT OFF MACHINE.

· STACKER IS PROVIDED WITH GEAR MOTOR AND VARIABLE SPEED DRIVE.

· MULTIPLE ROLLER ARE FIXED ON THE STACKER WITH CONTINUED DRIVE.

· ALL ROLLER ARE CONNECTED TO EACH OTHER WITH CHAIN GEAR DRIVE.

· THE STACK HOLDER IS LIFTED AND LOWERED BY PNEUMATIC CYLINDER.

· PANEL IS PROVIDED FOR MOVEMENT OF STACK AT 90 DEGREE

· THIS CAN BE USED MANUALLY AND AT AUTO MODE.

· STACK HOLDER ON MULTIPLE ROLLERS AT THE 90 DEGREE PLACED FOR ANY PICKUP AND MANUAL STACKING

· ARE PRESSURE FOR PNEUMATIC CYLINDER 8 KG (AIR COMPRESSOR NOT IN OUR SCOPE).

· MOTOR REQUIRED 03 HP 960 RPM -

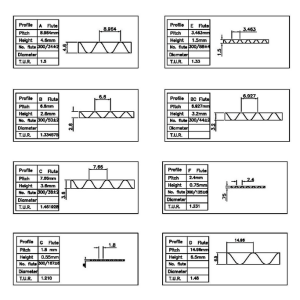

TAKE UP RATIO

TAKE-UP RATIO is the relation between the amount of medium paper and liner paper utilized by a single facer to produce corrugated board.

THREE METHODS USED TO MEASURE THE T.U.R.

1) Measuring feeding speed of paper.

TUR = medium paper speed / liner paper speed

2) Measuring the length of the corrugated board

T.U.R. = Medium paper used to produce certain length of board/Liner paper used to produce the same length of board

3) Using a Take Up Ratio Monitor

The most accurate method of all, accurate to the third decimal point, i.e. 1.326 plus or minus 0.001 is the T.U.R. monitor.

-

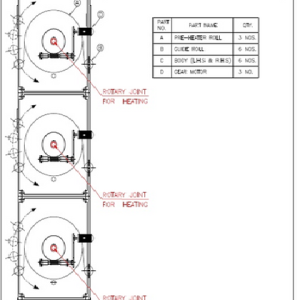

TRIPLEX PRE HEATER

TRIPLEX PRE HEATER

DIAMETER – 762 MM

PRE HEATER ENHANCED HEAT CONDUCTION MOTORIZED WRAP ANGLE ADJUSTMENT RANGE 60 DEGREE – 220 DEGREE THREE SETS ARE FIXED ONE OVER THE OTHER 2 SETS ARE USED FOR 2 PLY LINER AND BOTTOM SET IS USED BOTTOM PAPER.

THE WRAP AROUND SYSTEM HELP IN MAINTAINING PERFECT HEAT OF TO ALIVE PROPER PERFORMANCE (SPEED) AND BOUNDING OF BOARD CONTROL PANEL WITH REVERSE FORWARD STARTERS FIXED ON THE MACHINE PRE HEATER DRUM AND SHEET GRINDING ROLLS ARE HARDCROME. IT’S WORKING PRESSURE IS 1.1 – 1.2 MPA. METAL SORT PIPE (SYPHONE) ARE NEEDED TO BE FIXED FOR PERFECT DRAIN.

-

WEB ALIGNMENT UNIT

Web Alignment Unit

MACHINE DESCRIPTION:

▪ THE MACHINE IS FIXED ON THE OVERHEAD BRIDGE.

▪ WORKING OF THIS MACHINE IS TO ALIGN AND ADJUST LINERS OF BOTH CORRUGATION MACHINES.

▪ VACUUM SUCTION PUMPS ARE FIXED TO PROVIDE PROPER TENSION OF BOTH CORRUGATION MACHINE’S. THIS SYSTEM PROVIDES PERFECT TENSION CONTROL WHILE FEEDING THE USER IN BAKER STAND.

▪ THE PERFECT TENSION HELP’S IN ACHIEVING MINIMUM GLUE APPLICATION ON THE LINERS OF BOTH CORRUGATION M/C’S.

▪ THE LEFT AND RIGHT ALIGNMENT IS CONTROLLED WITH GEAR MOTOR’S AND SCREW SYSTEM.

▪ ALL GEAR MOTORS ARE SYNCHRONISED AND CONTROLLED THROUGH A CONTROL PANEL FIXED AND PROVIDED ALONG WITH THE MACHINE.

▪ 3 H.P. VACCUME PUMP IS FIXED ON WEB ALLIGNMENT UNIT.

▪ REVERSE / FORWARD STARTERS ARE FIXED.

▪ OPERATE TO ALIGN THE 2 PLY LINER.

▪ AS WEB 1 H.P. X 2 = 2 H.P. IS USED FOR WEB ALIGNMENT.

▪ 3 H.P IS USED FPR VACUM SUCTION.

▪ TOTAL 5 H.P. IS USED FOR WEB ALIGNMENT UNIT.