Description

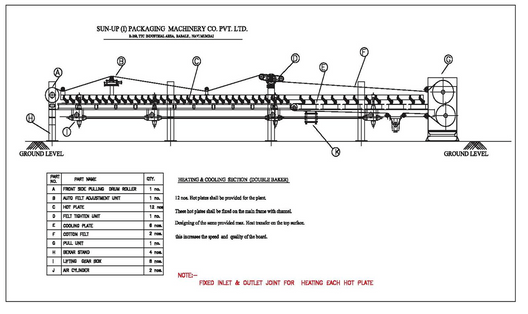

HOT PLATE SECTION

MACHINE DESCRIPTION

· THE DOUBLE FACER IS CORRUGATED PAPER ENTER INTO HOT PLATES AND MOULDING AFTER PASTED GLUE, AND BECOME INTO BOARD AFTER COOLING.

· HOTPLATE: MADE FROM STEEL SPECIAL BOILER PLATE / DESIGNED FOR GAS HEATING.

· THE SURFACE EXPERIENCED GRINDING, AND POLISHING TREATMENT, CLEAN UP THE UP THE WITHIN-STRESS AFTER JOINTED HOT PLATES, AND THAT ENSURE HEATED TEMPERATURE EQUABLY.

. EACH HOT PLATE HAS WEIGHT ROLLS WHICH PROVIDES PERFECT WEIGHT ON BOARD FOR BETTER BOUNDING AND MAINTAINING QUALITY.

· THE HOT PLATES ARE FIXED ON HEAVY DUTY CHANNEL FRAME, WHICH ARE GRINDED AND TREATED.

· THE CHANNEL FRAMES ON WHICH THE HOT PLATES ARE FIXED ARE FABRICATED / MACHINING AND PROPERLY ALIGNED.

· LATEST AUTO ALIGNMENT PNEUMATIC SYSTEM IS FIXED OVER THE HOTPLATES AND WEIGHT SHAFT SYSTEM.

· THIS AUTO ALIGNMENT UNIT HELP IN PERFECT ALIGNMENT OF TOP AND BOTTOM FELT.

· WHILE HIGH SPEED RUNNING OF PLANT NO OPERATOR IS NEEDED. TO ALINE TOP AND BOTTOM BELT. THIS SYSTEM IMPROVES MACHINE SPEED AND LIFE OF TOP AND BOTTOM BELT’S LIFE.

· LET IT BE 3 PLY OR 5 PLY BOARD TRAVEL ON HOT PLATES AND COOLING PLATES THE BOARDS IS COMPRESSED FOR PERFECT BOARD QUALITY.

· BY WEIGHT SHAFT AND IMPORTED BELT- WHEN THE PLAN HAS TO STOP FOR ANY REASON MULTIPLE GEAR BOXES ARE FIXED ON THE HEAVY DUTY CHANNEL FRAMES HOLDING THE HOT PLATES AND COOLING PLATES.

· THIS MULTIPLE GEAR BOXES ARE OPERATOR BY HEAVY DUTY PNEUMATIC CYLINDER. THESE 2 NOS. PNEUMATIC CYLINDER LIFTS THE COMPLETE WEIGHT SHAFT SYSTEM. / AUTO WEIGHT ALIGNMENT BELT.

· ALL ARE LIFTED 8 TO 10” ABOVE THE HOT PLATE AND COOLING PLATES ALONG WITH THE BOARD WHICH IS ON THE HOT PLATES WHEN PLANT MUST HAVE STOPPED.

· THIS SYSTEM CAN BE OPERATED EVEN IF THERE IS A POWER SUPPLY SUDDEN CUT.

· DUE TO THIS SYSTEM THE LIFE OF BELT IMPROVES AS IT IS NOT IN CONTACT WITH HEATED HOT PLATE WHEN PLANT IS SUDDENLY/EMERGENCY/OR STOP DUE TO LINE BREAKAGE.

Reviews

There are no reviews yet.