- Your cart is empty Browse Shop

Showing 1–12 of 21 results

-

1.5 METER TWIN SHAFTLESS HYDRAULIC REEL STAND

1.5 METER TWIN SHAFTLESS HYDRAULIC REEL STAND

TECHNICAL DETAILS

- Hydraulic lifting AND lowering

- Symmetric clamping and unclamping based on centre line with hydraulic cylinder.

- Paper rolls transfer movement by hydraulic cylinder featuring line adjustment for paper roller alignment.

-

DOUBLE PROFILE MODEL: SDR –320

DOUBLE PROFILE MODEL: SDR –320.

ONE SET OF TOOL BOX WITH TOOL SET.

FLUTE ROLL:

· 2 SET OF FLUTE ROLL BEARING.

(ANY 2 SETS)

· ROLL 320 MM DIA (EN-24 MATERIAL) HARD CHROME PLATED. HARDEN UPTO 50 HRC.

· TOP ROLL 298 MM DIA (EN-24 MATERIAL) – HARD CHROME PLATED 50 HRC.

· PRESSURE ROLL DIA 320 MM (EN-9 MATERIAL) GRINDED HARD CHROME PLATED.

b) VACUUM JACKET FITTED ON THE PROFILES.

c) 1 SET OF FLUTE ROLLER CAN BE USED AT ONE TIME.

d) CHANGE THE FLUTE ROLL’S IN LESS THAN 3 MINUTES WITH HYDRAULIC POWER PACK.

e) PRE- SHOWERS FOR STEAM ARRANGEMENT.

f) REDUCTION GEAR BOX HEAVY DUTY

g) THE UP AND DOWN OF UPPER CORRUGATING ROLL IS OPERATED MECHANICALLY. BY SCREW SYSTEM AND MANUAL LOCKING IS PROVIDED.

h) COMPLETE ARRANGEMENT FOR GAS / ELECTRIC HEATING AS PER YOUR REQUIREMENT.

i) THERE ARE ARRANGEMENTS PROVIDED IN CORRUGATION MACHINE TO SET THE TAPPER OF THE FLUTE IF THERE IS ANY.

j) VACUUM SECTION BOX FITTED ON THE CENTRE FLUTE ROLLER (LATEST TYPE) FOR PAPER SUCTION INSTEAD OF ADOPTERS.

k) BLOWER’ SHALL BE USED FOR SUCTION ALONG WITH 20 H. P. MOTOR.

l) COMPLETE PIPE LINE WITH CLIPS SHALL BE PROVIDED ALONG WITH ALUMINIUM CASING FOR THE VACUUM BOX.

m) VARIABLE SPEED DRIVE 15 H. P. DRIVES IS ALSO BE PROVIDED TOUCH SCREEN..

n) GLUING ROLL AND DOCTOR ROLL HAVE BEEN ASSEMBLED PRECISE MICRO ADJUSTING DEVICE RESPECTIVELY FOR OBTAINING EXACT DISTANCE.

j) PRE-HEATING ROLL DIAMETER 300MM X 1 PC. FOR BOTTOM PAPER.

k) COMPLETE FRAME OF THE M/C IS FABRICATED FROM MILD STEAL TO ABSORB VIBRATION AND ACHIVE SPEED.

l) ALL FLUTE ROLLER’S AND PRESSURE ROLLER’S ARE FIXED ON DOUBLE BEARING SYSTEM.

EACH FLUTE ROLLER ARE FIXED ON 4 BEARING’S A- TOTAL OF 20 BEARING ARE FIXED FPR 2 SET’S OF FLUTE ROLLER AND ONE PRESSURE ROLLER. -

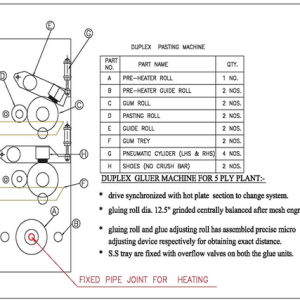

DUPLEX PASTING MACHINE UNIT

DUPLEX PASTING MACHINE

• LATEST INDIVIDUAL DRIVE SYSTEM FOR EACH LAYER SIMPLIFIES MECHANICAL STRUCTURED. UNUSED LAYERS CAN BE TURNED OF AND SO AS TO AVOID ENERGY WASTE. ONE UNIT CAN BE USED AT ONE TIME IF MACHINE IS RUNNING TO PRODUCE 3 PLY BOARD FOR 5 PLY BOTH UNITS ARE AUTOMATICALLY SYNCHRONIZED.

• ADJUSTMENT FOR GAPS BETWEEN APPLICATOR ROLL AND PRESSURE ROLL AND FINE TUNING ON INDIVIDUAL SAME SIDE GLUE SETTING AVAILABLE ON THE MACHINE. FREQUENCY CONVEYOR CONTROLLED AUTOMATICALLY VARIES WITH SPEED OF PRODUCTION LINE. ALSO KNOWN AS AUTOMATIC PORTING SYSTEM.

• DRIVE FROM MOTORS IS THROUGH TIMING BELTS TO AVOID ANY VARIATION ON GLUE APPLICATION ON LINER.

• PRE-HEATER FOR BOTTOM PAPER FIXED ON THE MACHINE FOR BETTER PERFORMANCE OF THE BOARD.

• A PERFECT DEGREE/ANGLE IS DESIGNED ON THIS MACHINE TO APPLY MINIMUM GLUE ON THE LINER.

• ARRANGMENT ARE PROVIDED IN THIS MACHINE TO CONTROLLED ANY FLUTE CRUSH WHILE GETTING GLUED. -

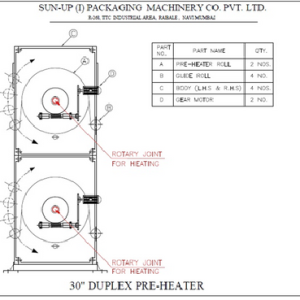

DUPLEX PRE HEATER

DUPLEX PRE HEATER

DIAMETER 762 MM

1.PRE HEATER ENHANCED HEAT CONDUCTION MOTORIZED WRAP ANGLE ADJUSTMENT RANGE 60 DEGREE – 220 DEGREE

2.THREE SETS ARE FIXED ONE OVER THE OTHER 2 SETS ARE USED FOR 2 PLY LINER AND BOTTOM SET IS USED BOTTOM PAPER.

3.THE WRAP AROUND SYSTEM HELP IN MAINTAINING PERFECT HEAT OF TO ALIVE PROPER PERFORMANCE (SPEED) AND BOUNDING OF BOARD

4.CONTROL PANEL WITH REVERSE FORWARD STARTERS FIXED ON THE MACHINE

5.PRE HEATER DRUM AND SHEET GRINDING ROLLS ARE HARDCROME. IT’S WORKING PRESSURE I5 1.1 – 1.2 MPA.

6.METAL SORT PIPE (SYPHONE) ARE NEEDED TO BE FIXED FOR PERFECT DRAIN. -

FELT ALIGNMENT UNIT-(PNEUMATICALLY AUTO CONTROLLED)

FELT ALIGNMENT UNIT-(PNEUMATICALLY AUTO CONTROLLED)

Technical Details

- The System is fixed on the felt unit “over the hot plates” to control the alignment of felt.

- It is adapted with a Pneumatic S.S. plate as guide to control the Left & right movement of felt.

- This system is provided to enhance the life of the felt.

- With this system we can increase the speed of plant as the system assures to keep the felt aligned at any speed.

- Provided with heavy duty guide roller & auto adjustable bearings.

- This system is used for both 3 ply & 5 ply plants

-

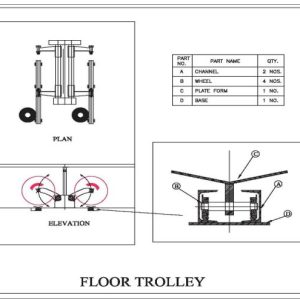

FLOOR TROLLEY

FLOOR TROLLEY

• THESE RAILING’S ARE INSTALLED BELOW FLOOR LEVEL. ONLY THE ROLL SHIFTING TROLLEY IS ABOVE THE FLOOR LEVEL.

• WITH EASY PUSH THE PAPER ROLL CAN BE LOADED ON THE TROLLEY.

• THE TROLLEY IS FIXED WITH BEARING AND RAILLY WHEEL MODE FROM MILD STEAL.

• THE UNDERGROUND RAILING HELP THE TROLLEY MOVE THE PAPER ROLL TO THE CENTER OF REEL STAND.

• THIS ARRANGEMENT HELP TO MOVE PAPER ROLL EASILY AND ALSO HELP IN LESS SPACE AS ROLL IS SHIFTED TO MAX 1.5 MTR. DECAL DESIGN.

• RAILING IS INSTALLED FOR EACH REEL LOADING ARRANGEMENT.

• EACH STAND IS SUPPLIED WITH TO 2 RAILING SYSTEM. -

HOT PLATE SECTION

HOT PLATE SECTION

- THE CHANNEL FRAMES ON WHICH THE HOT PLATES ARE FIXED ARE FABRICATED / MACHINING AND PROPERLY ALIGNED.

- LATEST AUTO ALIGNMENT PNEUMATIC SYSTEM ARE FIXED OVER THE HOTPLATES AND WEIGHT SHAFT SYSTEM.

- THIS AUTO ALLIGNMENT UNIT HELP IN PERFECT ALIGNMENT OF TOP AND BOTTOM FELT.

- WHILE HIGH SPEED RUNNING OF PLANT NO OPERATOR IS NEEDED. TO ALINE TOP AND BOTTOM BELT.

THIS SYSTEM IMPROVES MACHINE SPEED AND LIFE OF TOP AND BOTTOM BELT’S LIFE. - LET IT BE 3 PLY OR 5 PLY BOARD TRAVELLY ON HOT PLATES AND COOLING PLATES THE BOARDS IS COMPRESSED FOR PERFECT BOARD QUALITY.

- BY WEIGHT SHAFT AND IMPORTED BELT-WHEN THE PLAN HAS TO STOP FOR ANY REASON MULTIPLE GEAR BOXES ARE FIXED ON THE HEAVY DUTY CHANNEL FRAMES HOLDING THE HOT PLATES AND COOLING PLATES.

- THIS MULTIPLE GEAR BOXES ARE OPERATOR BY HEAVY DUTY PNEUMATIC CYLINDER THIS 2 NOS.PNEUMATIC CYLINDER LIFT THE COMPLETE WEIGHT SHAFT SYSTEM./ AUTO WEIGHT ALIGNMENT BELT.

- ALL ARE LIFTED 8 TO 10° ABOVE THE HOT PLATE AND COOLING PLATES ALONG WITH THE BOARD WHICH IS ON THE HOT PLATES WHEN PLANT MUST HAVE STOPPED.

- THIS SYSTEM CAN BE OPERATED EVEN IF THERE IS A POWER SUPPLY SUDDEN CUT.

- DUE TO THIS SYSTEM THE LIFE OF BELT IMPROVES AS IT IS NOT IN CONTACT WITH HEATED HOT PLATE WHEN PLANT IS SUDDENLY/EMERGENCY/OR STOP DUE TO LINE BREAKAGE.

-

HYDRAULIC MILL REEL STAND

HYDRAULIC MILL REEL STAND

• HYDRAULIC LIFTING OF LOWERING

• SYMMETRIC CLAMPING AND UNCLAMPING BASED ON CENTRE LINE WITH HYDRAULIC CYLINDER.

• PAPER ROLLS TRANSFER MOVEMENT BY HYDRAULIC CYLINDER FEATURING LINE ADJUSTMENT FOR PAPER ROLLER ALIGNMENT.

• ADJUSTABLE ECCENTRIC DEVICE FOR CHUCK BEARING SLEEVES ALLOWING NECESSARY ADJUSTMENTS ACCORDING TO PAPER ROLLS AND ROLLS KNOW AS CONICAL CHUCK FOR NEED HOLDING.

• CAN LIFT MAX PAPER ROLL DIA 1500 MM /300MM

• MAX LOADING CAPACITY OF MACHINE-2000 KG’S EACH SIDE.

• THE WEB TENSION IS CONTROLLED BY MULTI POINT PNUMATIC IMPORTED BREAKS.

• CONTROL PANEL FIXED FOR EASY OPERATION OF THE STAND.

• COMPLETE STAND IS FABRICATED WITH MILD STEEL – NO CASTING IS USED IN THE MANUFACTURING OF THIS UNIT.

• ALL HYDRAULIC PIPES AND KIT IS TOP QUALITY AND ASSURER’S LONG LIFE WITH MINIMUM AND VERY LOW COST MAINTAIN COST MAINTAIN. -

NC CUT-OFF

NC CUT-OFF:

MACHINE DESCRIPTION:▪ THIS MACHINE HAS SPECIAL STRUCTURE, BETTER INTENSITY, AND HIGH PRECISION, HIGH RIGIDITY GRINDING GEAR, HAND PRECISION KNIFE REST. HIGH SPEED CUT PLACID, LOW NOISE, AND DRIVE PART USE AC SERVE MOTOR, COOPERATE INDUSTRY COMPUTER TO CONTROL SYSTEM, CONVENIENT TO OPERATE.

-

OVER HEAD BRIDGE CONVEYOR

OVER HEAD BRIDGE CONVEYOR

- All bridge structures will use Channel, Angle and Steel CHEQUERS Plate etc.,

- Two Sets take-up conveyor installed upon each Single Facer.

- Two layers level – type conveyor to guide Single face from Single facer to Triplex pre-heater.

- Paper width right and left motion by manual adjustment.

- To be supplied with one set of WALK WAY AND TWO SETS OF STAIRCASE..

-

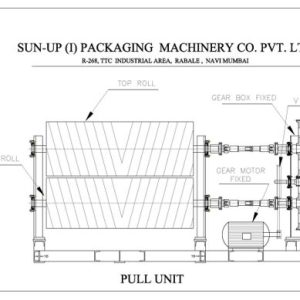

PULL UNIT SYSTEM

PULL UNIT SYSTEM:

MACHINE DESCRIPTION:

▪ THE DIAMETER OF THE UPPER ROLL IS DIA 650MM, THE DOWN ROLL IS DIA 600MM, AND COVERED WITH WEAR-RESISTANT, RUBBER GLADDING IS DONE WITH SPECIAL COATING AND THREADING, THESE THREAD LINES OF THE UPPER AND DOWN ROLL IS REVERSE. THIS IS DONE TO RUN THE FELT WITH PROPER ALIGNMENT AND HELPS IN AVOIDING DAMAGE TO THE FELT.

▪ THE GEAR IS MADE FROM HIGH QUALITY ALLOY STEEL, AND THE SURFACE IS HEATED AND GRINNED AND IT IS HIGH PRECISION, HIGH STRENGTH, LOW NOISE, BIG PASSING SQUARE, AND CONVENIENT FOR SERVICING AND MAINTAINING.

▪ THESE ROLLER WITH THE HELP OF GEARS DRIVES MOVE THE FELT TO OVER THE HOT PLATES AND COOLING PLATES.

▪ HEAVY DUTY TRANSMISSION SHAFTS ARE PROVIDED TO ROTATE THESE HEAVY DUTY ROLLERS.

▪ DESIGN MADE FOR TROUBLE FREE OPERATION OF THE PLANT. -

SDR 300 – DOUBLE PROFILE CORRUGATION MACHINES

SDR 300 – DOUBLE PROFILE CORRUGATION MACHINES

FLUTE ROLL:

- 2 SET OF FLUTE ROLL BEARING (ANY 2 SETS)

- ROLL 320 MM DIA (EN-24 MATERIAL) HARD CHROME PLATED. HARDEN UPTO 50 HRC.

- TOP ROLL 298 MM DIA (EN-24 MATERIAL) – HARD CHROME PLATED 50 HRC.

- PRESSURE ROLL DIA 320 MM (EN-9 MATERIAL) GRINDED HARD CHROME PLATED.

- VACUUM JACKET FITTED ON THE PROFILES.

- 1 SET OF FLUTE ROLLER CAN BE USED AT ONE TIME.

- CHANGE THE FLUTE ROLL’S IN LESS THAN 3 MINUTES WITH HYDRAULIC POWER PACK.

- PRE- SHOWERS FOR STEAM ARRANGEMENT.

- REDUCTION GEAR BOX HEAVY DUTY