Description

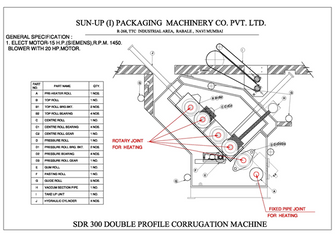

SDR 300 – DOUBLE PROFILE CORRUGATION MACHINES

FLUTE ROLL:

- 2 SET OF FLUTE ROLL BEARING (ANY 2 SETS)

- ROLL 320 MM DIA (EN-24 MATERIAL) HARD CHROME PLATED. HARDEN UPTO 50 HRC.

- TOP ROLL 298 MM DIA (EN-24 MATERIAL) – HARD CHROME PLATED 50 HRC.

- PRESSURE ROLL DIA 320 MM (EN-9 MATERIAL) GRINDED HARD CHROME PLATED.

- VACUUM JACKET FITTED ON THE PROFILES.

- 1 SET OF FLUTE ROLLER CAN BE USED AT ONE TIME.

- CHANGE THE FLUTE ROLL’S IN LESS THAN 3 MINUTES WITH HYDRAULIC POWER PACK.

- PRE- SHOWERS FOR STEAM ARRANGEMENT.

- REDUCTION GEAR BOX HEAVY DUTY

- THE UP AND DOWN OF UPPER CORRUGATING ROLL IS OPERATED MECHANICALLY. BY SCREW SYSTEM AND MANUAL LOCKING IS PROVIDED.

- COMPLETE ARRANGEMENT FOR STEAM HEATING AS PER YOUR REQUIREMENT.

- THERE ARE ARRANGEMENTS PROVIDED IN CORRUGATION MACHINE TO SET THE TAPPER OF THE FLUTE IF THERE IS ANY.

- VACUUM SECTION BOX FITTED ON THE CENTRE FLUTE ROLLER (LATEST TYPE) FOR PAPER SUCTION INSTEAD OF ADOPTERS.

- BLOWER’ SHALL BE USED FOR SUCTION ALONG WITH 20 H. P. MOTOR.

- COMPLETE PIPE LINE WITH CLIPS SHALL BE PROVIDED ALONG WITH ALUMINIUM CASING FOR THE VACUUM BOX.

- VARIABLE SPEED DRIVE 15 H. P. DRIVES IS ALSO BE PROVIDED TOUCH SCREEN..

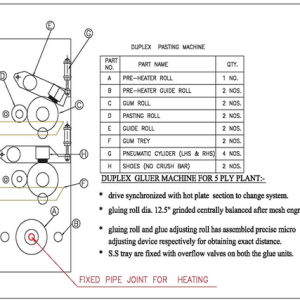

- GLUING ROLL AND DOCTOR ROLL HAVE BEEN ASSEMBLED PRECISE MICRO ADJUSTING DEVICE RESPECTIVELY FOR OBTAINING EXACT DISTANCE.

- PRE-HEATING ROLL DIAMETER 300MM X 1 PC. FOR BOTTOM PAPER.

- COMPLETE FRAME OF THE M/C IS FABRICATED FROM MILD STEAL TO ABSORB VIBRATION AND ACHIVE SPEED.

- ALL FLUTE ROLLER’S AND PRESSURE ROLLER’S ARE FIXED ON DOUBLE BEARING SYSTEM.

EACH FLUTE ROLLER ARE FIXED ON 4 BEARING’S A- TOTAL OF 20 BEARING ARE FIXED FOR 2 SET’S OF FLUTE ROLLER AND ONE

PRESSURE ROLLER.

ONE SET OF TOOL BOX WITH TOOL SET.

Reviews

There are no reviews yet.