Description

DOUBLE PROFILE MODEL: SDR –320.

FLUTE ROLL:

· 2 SET OF FLUTE ROLL BEARING.

(ANY 2 SETS)

· ROLL 320 MM DIA (EN-24 MATERIAL) HARD CHROME PLATED. HARDEN UPTO 50 HRC.

· TOP ROLL 298 MM DIA (EN-24 MATERIAL) – HARD CHROME PLATED 50 HRC.

· PRESSURE ROLL DIA 320 MM (EN-9 MATERIAL) GRINDED HARD CHROME PLATED.

b) VACUUM JACKET FITTED ON THE PROFILES.

c) 1 SET OF FLUTE ROLLER CAN BE USED AT ONE TIME.

d) CHANGE THE FLUTE ROLL’S IN LESS THAN 3 MINUTES WITH HYDRAULIC POWER PACK.

e) PRE- SHOWERS FOR STEAM ARRANGEMENT.

f) REDUCTION GEAR BOX HEAVY DUTY

g) THE UP AND DOWN OF UPPER CORRUGATING ROLL IS OPERATED MECHANICALLY. BY SCREW SYSTEM AND MANUAL LOCKING IS PROVIDED.

h) COMPLETE ARRANGEMENT FOR GAS / ELECTRIC HEATING AS PER YOUR REQUIREMENT.

i) THERE ARE ARRANGEMENTS PROVIDED IN CORRUGATION MACHINE TO SET THE TAPPER OF THE FLUTE IF THERE IS ANY.

j) VACUUM SECTION BOX FITTED ON THE CENTRE FLUTE ROLLER (LATEST TYPE) FOR PAPER SUCTION INSTEAD OF ADOPTERS.

k) BLOWER’ SHALL BE USED FOR SUCTION ALONG WITH 20 H. P. MOTOR.

l) COMPLETE PIPE LINE WITH CLIPS SHALL BE PROVIDED ALONG WITH ALUMINIUM CASING FOR THE VACUUM BOX.

m) VARIABLE SPEED DRIVE 15 H. P. DRIVES IS ALSO BE PROVIDED TOUCH SCREEN..

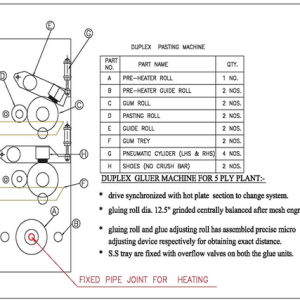

n) GLUING ROLL AND DOCTOR ROLL HAVE BEEN ASSEMBLED PRECISE MICRO ADJUSTING DEVICE RESPECTIVELY FOR OBTAINING EXACT DISTANCE.

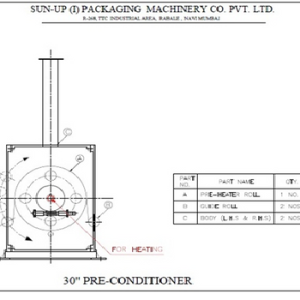

j) PRE-HEATING ROLL DIAMETER 300MM X 1 PC. FOR BOTTOM PAPER.

k) COMPLETE FRAME OF THE M/C IS FABRICATED FROM MILD STEAL TO ABSORB VIBRATION AND ACHIVE SPEED.

l) ALL FLUTE ROLLER’S AND PRESSURE ROLLER’S ARE FIXED ON DOUBLE BEARING SYSTEM.

EACH FLUTE ROLLER ARE FIXED ON 4 BEARING’S A- TOTAL OF 20 BEARING ARE FIXED FPR 2 SET’S OF FLUTE ROLLER AND ONE PRESSURE ROLLER.

ONE SET OF TOOL BOX WITH TOOL SET.

Reviews

There are no reviews yet.